Atomistic Deformation Mechanisms in Advanced Structural Materials

Leveraging strength versus ductility relations in bcc high-entropy alloys from first-principles.

Body-centered cubic (bcc) high-entropy alloys (HEAs) often suffer from a trade-off between strength and ductility, with some compositions exhibiting exceptional resistance to thermal softening but suffering from brittle failure at room temperature, while others show remarkable toughness at cryogenic temperatures but experience a significant decrease in yield stress as temperature increases. Using first-principles calculations, we show that intrinsic ductility is closely correlated with incipient structural instabilities in the bcc phase. These instabilities are associated with softening of the vibrational properties of the bcc lattice, which has important implications for phase competition, local lattice distortions, screw dislocation core structure, and unstable stacking fault energy. Further, we demonstrate that increasing concentrations of hcp elements (Ti, Zr, Hf, and Re) are linked to key signatures in the electronic structure, reflected by the Rice intrinsic ductility criterion. Additionally, we propose that the addition of oxygen interstitial atoms is a promising avenue to improve the alloy strength without jeopardizing ductility. In detail, the accommodation of oxygen atoms not only induces distortion in the lattice leading to strengthening effects but also might be associated with the formation of ordered complexes that enhance strain hardening and delay unstable plastic deformation.

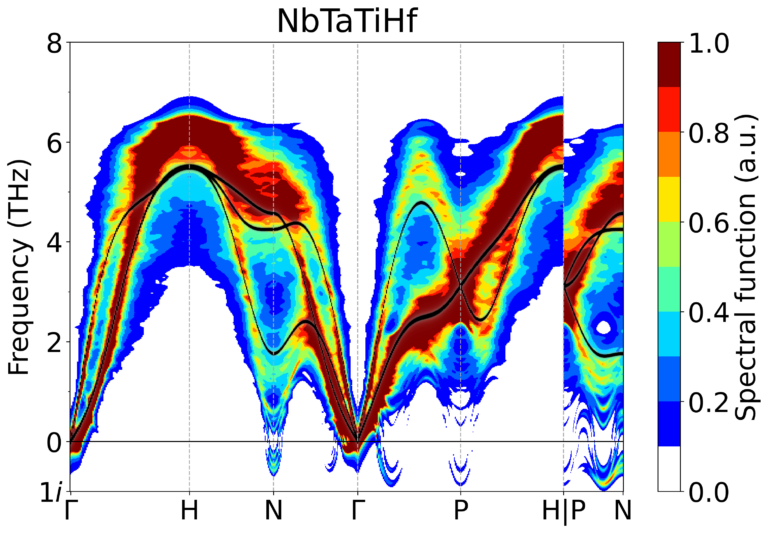

Phonon spectral function for bcc NbTaTiHf. The color map indicates phonon spectral functions, including both mass and force fluctuations, while black solid lines show results obtained using the virtual-crystal approximation.

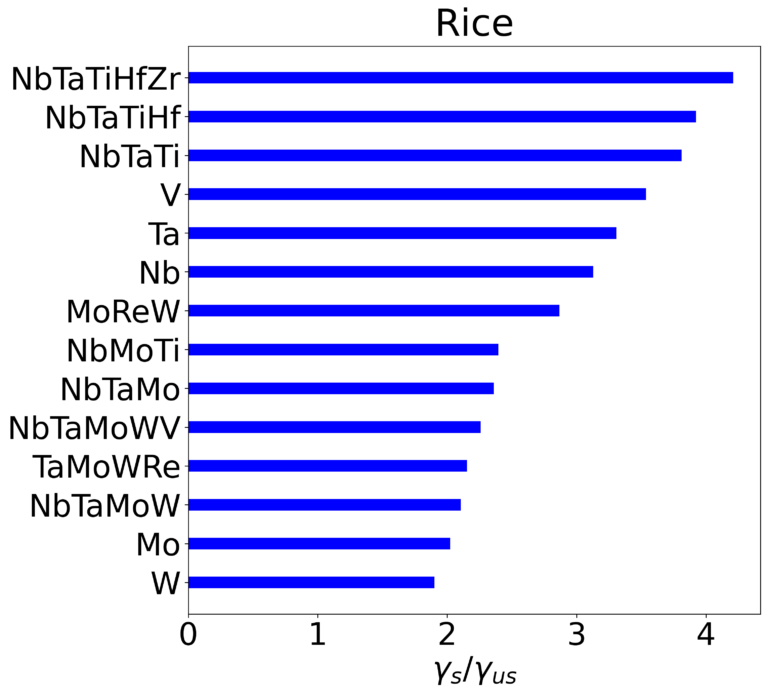

Rice intrinsic ductility parameter for bcc metals and alloys. The surface and unstable stacking fault energies are calculated for the {110} slip plane, and the material compositions on the vertical axis are presented in ascending ductility order.

Solution energies of oxygen (O) interstitial atoms in octahedral sites in bcc NbTaTiHf. Solution energy values are obtained from first-principles calculations, and using a cluster expansion (CE) model parameterized with DFT results.

This research was primarily supported by the Materials Sciences and Engineering division of the US Department of Energy, Office of Science, Office of Basic Energy Sciences through the Damage-Tolerance in Structural Materials program (KC13) at the Lawrence Berkeley National Laboratory (LBNL) under contract DE-AC02-CH11231.