Multiscale Modeling of Corrosion and Irradiation in Reactor Extremes

We are a key partner in an Energy Frontiers Research Center (EFRC) called “FUTURE,” or Fundamentals of Transport Under Reactor Extremes. Our work aims to understand the thermodynamics and kinetics that drive microstrucutural evolution in metals under corrosion and irradiation, through the use of numerical simulations at multiple length-scales to probe solid-liquid interface reactions, defect migration in metal-oxide systems, and intergranular corrosion/transport phenomena.

Chromium Solvation in Molten Fluoride Salts

Molten salts are excellent high temperature solvents forspecialized applications. These include for coolants/thermal transport media in solar thermal towers and Generation IV nuclear reactor designs. The challenge of molten salt corrosion remains a barrier towards properly utilizing molten salts in these applications. In Gen. IV nuclear reactors, this is shown most prominently by the high degree of selective dealloying and dissolution of Cr from structural metals (both steels and Ni-based alloys such as Hastelloy-N).

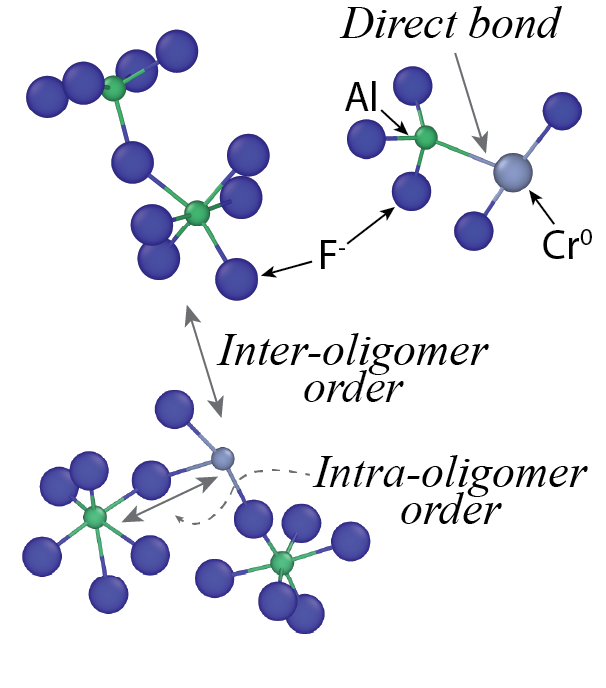

In order to understand and ultimately prevent corrosion, a fundamental understanding of the molten salt solvents is required. As a part of FUTURE, the Asta Group focuses on understanding the structure, thermodynamics, and transport of molten fluorides. Previously, the Asta Group has published on the short- and medium-range ordering of Cr solutes in molten 2KF-NaF, 2LiF-BeF2, and 3LiF-AlF3 solvents.

We are interested in understanding the structure and dynamics of the electrochemical double layer in molten fluorides. We are especially interested in the connection between bulk salt fluoro-acidity and the subsequent medium-range ordering within the double layer. The connection between these, and their dependence on the temperature and interface voltage, can help guide understanding of the transport of corrosion products from the interface to the bulk solvent.

Mesoscale Modeling of Corrosion and Irradiation Effects on Microstructure

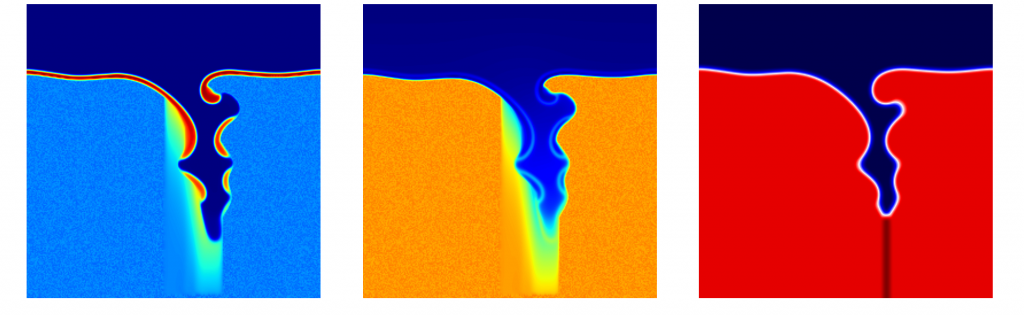

Insights gained from ab-initio simulations are combined in a mesoscale model to predict the overall microstructure evolution of metals in reactor extremes. Using phase-field modeling, the Asta group is studying how corrosion depth and morphology in molten-salt/metal systems are controlled by reactions at the solid-liquid interface, long-range diffusion of species in the molten salt, and microstructural features in the metal. In particular, we have found that dealloying at high-energy grain boundaries causes deep, localized corrosion fronts, which can leave “worm-hole” morphologies in their wake. Under effects of radiation, enhanced kinetics in the metal are found to lead to more homogenous corrosion fronts. These conclusions are vital to designing and employing advanced steels in nuclear reactors.

This project is supported by the Department of Energy (DOE) Office of Basic Energy Sciences.